MRWA Supplement to Austroads Guide to Road Design - Part 5B - Drainage: Open Channels, Culverts and Floodways

Table of Contents

This Supplement has been developed to be read in conjunction with Austroads Guide to Road Design (GRD) Part 5B: Drainage – Road Surface, Networks, Basins and Subsurface (2013), a copy of which can be purchased via the Austroads website.

In Western Australia, Main Roads' policies, guidelines and standards take precedence over Austroads Guides and Standards Australia Standards. National Guides and Standards take precedence over International Guides and Standards, unless specifically stated otherwise.This Supplement has the same structure as the equivalent Austroads Guide and only additional requirements, clarifications, or practices different from Austroads appear. Where appropriate, this Supplement may also contain additional sections and figures not covered by Austroads, but the numbering sequence found in the Austroads Guide remains. Figures and tables in this Supplement replace those with the same figure or table number in the equivalent Austroads Guide.

1. Introduction

Main Roads has no supplementary comments for this section.

2. Open Drains and Channels

2.1.4 Types of Open Drains

Main Roads’ open drain naming convention and typical sections shall be per Guideline Drawings 9831-5497 and 9831-5498.

2.2 General Considerations

It is good practice that the drainage construction does not lag behind the formation earthworks as substandard construction could result from working on undrained soils and damage to new earthworks may occur from rain events where there is insufficient drainage provision.

2.3.3 Fundamental Equations

Other sources of Manning’s values include Argue (1986) and I.E.Aust (2001).

2.7.1 Open Channel Design - Design Methodology

Freeboard discussed in Section 2.7.1 is more suited to larger open drains that do not necessarily form part of the road formation. Refer to Section 2.13 in AGRD 5B for freeboard more applicable to roadside drains.

For permissible velocities suitable for non-vegetated, constructed open drains Main Roads also recommend the following guidance:

|

Type of Material in Excavation |

Permissible Velocity (m/s) |

|

|

Intermittent Flow |

Sustained Flow |

|

|

Fine Sand (Noncolloidal) |

0.8 |

0.8 |

|

Sandy Loam (Noncolloidal) |

0.8 |

0.8 |

|

Silt Loam (Noncolloidal) |

0.9 |

0.9 |

|

Fine Loam |

1.1 |

1.1 |

|

Stiff Gravel |

1.2 |

1.1 |

|

Stiff Clay (Colloidal) |

1.5 |

1.2 |

|

Graded Material (Noncolloidal) |

||

|

-Loam to Gravel |

2.0 |

1.5 |

|

-Silt to Gravel |

2.1 |

1.7 |

|

-Gravel |

2.3 |

1.8 |

|

-Corse Gravel |

2.4 |

2.0 |

|

-Gravel to Cobbles (Under 150mm) |

2.7 |

2.1 |

|

-Gravel and Cobbles (Over 200mm) |

3.0 |

2.4 |

Table 2.1 Recommended Permissible Velocities for Unlined (Bare Soil) Drains

(Source: Caltrans Highway Design Manual, Table 862.2, 2006).

2.10 Channel Drops

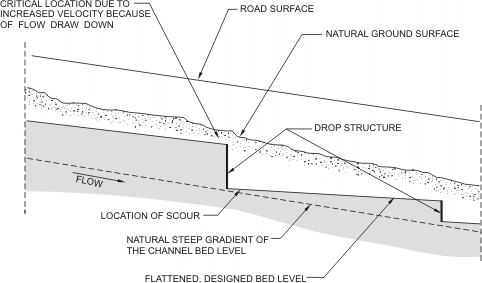

Although not in common use by Main Roads, drop structures are used for flow control and energy dissipation. They work by reducing the drain slope by placing drop structures at intervals along the drain thereby changing a continuous, steeper sloped drain into a series of milder sloped reaches with vertical drops. As shown in Figure 2.1, drop structures change the slope of the drain so that high erosion producing velocities are not developed.

|

|

The following is the design procedure:

- Carry out an open drain analysis to identify the peak design flow velocity using the slope of the table drain.

- Make an examination of the soil types in the drain.

- Check these velocities against the maximum permissible velocity for typical soil types as given in Section 2.7.1 above. Regrade the bed slope and repeat open drain analysis to ensure velocities do not exceed the scouring velocities for the particular soil type.

- The extent of the flattened bed gradient should be judiciously located to ensure adequate cross section area for the designed peak flow as the bed slope approaches the surface at the downstream end.

- Provide a vertical drop of sufficient depth to ensure reasonable length of drain before the next drop structure is required.

- In order to ensure adequate waterway area and avoid spillage from the drop structure, an estimation for critical depth analysis is required. As a guide, the vertical depth between the top of the drop structure and the top of the side slope should be at least the same depth as the designed critical depth.

In undertaking the design of these structures on curves it is generally recognised that the drain radius is similar to the radius of the road and the rise of water level on the outer curve is not significant and can therefore be ignored.

2.12.1 Design of Edge and Median Drains

The document refers to section 2.15 – Catch Drains and Catch Banks for the design procedure for inlets within these drains. Section 2.15 does not actually provide guidance. Designers can instead refer to the empirical relationships within Section 5.5 of AGRD 5A suitably modified to reflect the shape of such drains relative to the kerbed channels on which the formula are based.

2.13.2 Table Drain Blocks

Typical section for a table drain block is as per MRWA Guideline Drawing 9831-5498

2.13.3 Diversion Drains and Diversion Blocks

The required spacing for offshoot or diversion drains may be less stringent than that indicated in AGRD 5B and is a function of the flow in the drain. Typical spacing ranges from 150m to 300m in undulating terrain, reducing to 100 m in steeper topography.

3. Culverts

3.1 Introduction

The design of culverts should be in accordance with Main Roads’ Standard Drawings for culverts. The drawings cover different culvert types and materials including reinforced concrete pipe (RCP’s), reinforced concrete boxes (RCB’s) and corrugated steel pipes (CSP’s).

3.2 Information Required

Gathering of information is important during site investigation. The items below represent the information that can be obtained from the site:

- Scour and outlet protection at similar culverts in the vicinity (this will provide valuable guidance for design of outlet protection).

- Estimate of stream velocity, slope, and alignment. This information can also be used to verify design flows. Refer to AGRD Part 5 and MRWA’s Supplement.

- Presence of shrubs and trees on eroding banks.

- Watershed land uses, particularly logging, cultivation, and construction.

- Soil characteristics.

- Manning's roughness coefficient.

- Storage of debris and materials within the flood plain (logs, lumber, solid waste, etc.) as this material could govern the minimum size of culvert to be used.

- Anecdotal information on the performance of any existing drainage.

Some culvert sites may require a specialist Waterway Investigation Survey and this should be carried out in accordance with Main Roads Guide to Specialised Survey Applications.

3.4.2 Materials

In addition to groundwater pressures, floatation may occur from buoyant uplift forces at the culvert occurring primarily at the culvert inlet which may be great enough to dislodge the embankment. High inlet velocities can also pull unanchored inlet edges into the barrel causing blockage and additional damage.

Precautionary measures should be assessed during design of culverts, these include:

- Avoiding

- Protecting

- Anchorage

The choice of culvert material will depend largely on the in-situ ground conditions and whether the ground conditions have been assessed as “Aggressive” or “Non-Aggressive”. Further information on this assessment and the impact it has on culvert materials may be found in Specification 404 – Culverts Annexure 404A.

Refer AGRD Part 5A Section 6.6.5 for generic Manning’s ‘n’ values applicable to concrete culverts. In the absence of manufacturer information Table 3.1 may be used for Manning’s ‘n’ values applicable to corrugated steel pipes. Manning’s ‘n’ values applicable to plastic pipe should be sourced from the applicable manufacturer.

|

Diameter (mm)

|

Manning's Coefficient (n) |

||

|

Corrugations - Pitch X Depth (mmxmm) |

|||

|

|

68X13 |

75X25 |

125X25 |

|

300 |

0.011 |

# |

# |

|

375 |

0.012 |

# |

# |

|

450 |

0.013 |

# |

# |

|

600 |

0.015 |

# |

# |

|

750 |

0.017 |

# |

# |

|

900 |

0.018 |

0.022 |

# |

|

1050 |

0.019 |

0.022 |

# |

|

1200 |

0.020 |

0.023 |

0.022 |

|

1350 |

0.021 |

0.023 |

0.022 |

|

1500 |

0.021 |

0.024 |

0.023 |

|

1650 |

0.021 |

0.025 |

0.024 |

|

1800 |

0.021 |

0.026 |

0.024 |

|

1950 & Larger |

0.021 |

0.027 |

0.025 |

Table 3.1 Manning's n value for Helically Wound Corrugated Steel Pipes (Source: AISI; 1999)

Note: # Indicates that no pipes are available in this pitch x depth.

3.5.1 Minimum Culvert Size Allowable

The following minimum culvert sizes used by Main Roads are as follows:

- Pipe culvert size 450mm nominal diameter*

- Minimum box culvert size 1200 x 375mm.

*375 mm diameter may be specified in special circumstances

3.5.2 Other Sizing Considerations

Culverts that have a waterway area greater than 3.0m² shall be subject to a formal Waterways Analysis as outlined in the Procedure for Waterways Investigation and Design section of the “Structures Engineering Management Systems Manual”.

3.6 Structural Requirements

Culverts used on Main Roads projects must meet the performance requirements specified in Specification 404 – Culverts.

3.6.3 Space between Pipes in Multiple-Barrel Culverts

The installation requirements applicable to multi-barrel culverts shall be in accordance with Standard Drawing 200131-0061.

3.6.4 Cover

Cover requirements for RCB’s shall be as indicated on Main Roads Standard Drawings.

The minimum cover for corrugated metal pipes should be determined in accordance with AS / NZS 2041 Buried Corrugated Metal Structures (2011). Refer also to AGRD Part 5 Appendix B. As a guide the minimum cover for Helical Lock-seam Corrugated Steel Pipes should be 0.6m for Highway Live Loads and 1.0m for Railway Live Loads. Larger diameter pipe (i.e. > 3.6m) may require additional cover.

Minimum cover for plastic pipes should be in accordance with Table 5.1 of AS/NZS 2033: Installation of Polyethylene Pipe Systems.

Culvert sections, including link slabs, must not protrude into the pavement layer unless there are project specific constraints that dictate the need. Prior approval from Main Roads relevant asset manager must be obtained in this instance.

3.7.2 Outlet Velocity

Where velocities exceed the scourable limit of the downstream natural material, outlet rock protection in accordance with Table 4.1 should be placed.

3.7.5 Allowable Headwater (AHW)

In instances where the headwater level remains at the top of road subgrade level or higher for periods longer than 24 hours the pavement should be designed using soaked CBR values for the subgrade. Note that this is applicable for storms up to the 20 year ARI event.

3.10 Design Procedures

The following information shall accompany the culvert design:

-

- Basis for the calculation of the flows.

- Design recurrence interval both for the culvert and scour protection.

- Outlet velocity.

- Condition culvert is expected to operate under e.g. inlet or outlet control.

- Maximum headwater value used for the culvert.

- Any assumptions used in sizing of the culvert.

- Method used for calculating culvert size e.g. nomograph, computer program etc.

- Culvert cross sections indicating road reference line and offsets to headwalls (these can be hand drawn).

- Culvert schedule.

- Pipe bedding.

- Degree of pipe support assumed in determining pipe class (if concrete) or wall thickness for steel culverts.

- Observations made during site visits which have been used to determine or justify extent or lack of outlet protection.

- Installation condition.

3.13 Culvert Outlet Protection

Main Roads practice is to provide rock protection in accordance with the Floodway Design Guide, reproduced in AGRD Part 5 Section 3.6.5.

For minor culverts it is not expected that flow duration for low frequency flows will be extended for periods that could cause serious scour problems and as such rock protection is not generally provided. However due to some site specific conditions scour protection may be required.

Refer also to MRWA Standard Drawings for culvert outlet rock protection details.

3.14 Culvert End Treatments

Refer to MRWA Standard Drawings for culvert end treatment details.

3.14.3 Traversable End Treatments

For limitations on the use of traversable end treatments, refer to Main Roads supplement to Austroads Guide to Road Design Part 6: Roadside Design, Safety and Barriers

4. Floodways

MRWA document Floodway Design Guide 2006 takes precedence over this section.

5. References

Argue, J.R, Storm Drainage Design in Small Urban Catchments: A Hand Book for Australian Practice. Special Report No. 34, Australian Road Research Board, Vermont South, (1986).

Institute of Engineers Australia, Australian Rainfall and Runoff, A Guide to Flood Estimation, Volume I and II, (2001).