Spotting for Longitudinal Line Marking Guideline

Table of Contents

Spotting for Longitudinal Line-marking

1. Purpose

The purpose of this guideline is to describe the recommended practice and procedure for spotting (marking out) of road surfaces in preparation for longitudinal line-marking for Main Roads Western Australia.

2. General

It is advised that the parties undertaking the spotting liaise with the line-marking parties on each project to determine specifics that may best suit the line-marking.

2.1 Safety

Spotting for longitudinal line-marking involves working within trafficable lane areas with the potential to expose workers to serious hazard.

All relevant and necessary safety standards, policies and traffic management standards and practices of Main Roads Western Australia must be complied with when undertaking spotting for longitudinal line-marking of roads.

2.2 New Roads vs Spotting as Part of Maintenance Works

Spotting for lines on new roads/new works is generally set-out from design data/strings. Set-out positioning equipment and methodologies must be capable of attaining accuracies to result in an appropriately smooth and correctly positioned line. This may be subject to project specific construction set-out requirements, which must be abided.

Conversely, spotting as part of maintenance works involves evaluation of the road environment and fitting lines of best fit. The emphasis is on smooth lines whilst not deviating more than 15mm from the mean centreline on straights and 200mm from the true centreline on curves.

2.3 Spots

Spots should be provided in permanent white paint. In the case of a light coloured road surface a more suitable colour may be considered for use to improve contrast and visibility.

Spots need to be of sufficient diameter to be clearly visible to the operator of the line-marking truck/plant. The recommended size for use with line-marking trucks is 50 mm (±10 mm) in diameter.

Any incorrectly marked spots should be completely removed with permanent black paint in order to create a single, clearly defined alignment for the operator of the line-marking plant to follow.

Spotting should not be undertaken while the road surface is wet.

3. Spotting for Road Marking

3.1 Spotting of Straight Sections of Road

Spots should be marked within ±15 mm of the mean centreline at sufficiently close intervals for the alignment to be clearly visible. The recommended spacing on straight sections of road for use with line-marking trucks is at 8 metre intervals, or as arranged with line-marking parties for best and most efficient progress and outcome.

Spots should provide an accurate, smooth and regular alignment for the operator of the line marking truck to establish a line of acceptable standard and appearance.

Lines to be marked in areas where bends or kinks exist in the mean centreline should be spotted with a smooth curve to remove the kink. Furthermore, where possible these curved kinks should be placed to coincide with crests. They should avoid areas of sag. This results in the shift of the kink to be less noticeable in the line-marking.

Where the edge is uneven, an average or 'line of bitumen' should be used in order to best define the optimum mean centreline.

3.2 Spotting of Curved Sections of Road

Spots should not deviate more than 200mm from the actual centre-line of the road through the entire curve and at tangents.

The spots should be marked at sufficiently close intervals to be clearly visible to the operator of the line marking truck. The recommended spacing on curves for use with line marking trucks is at 5 metre intervals, or as arranged with line-marking parties for best and most efficient progress and outcome.

The spots must delineate a smooth curve free of visible kinks.

3.3 Spotting for Edge Lines

Spotting for edge lines is required when:

- Variation of the road width requires the tapers to be spotted

- Repairs on the road edges have removed sections of the existing edge line

- Tying into existing edge lines

The recommended practice is to spot for approximately 30 metres from the existing edge line to enable the line marking truck to match the new line to the existing.

3.4 Spotting for Overtaking Lanes

The centreline, each lane and all tapers for edge lines should be spotted for overtaking lanes.

3.5 Spotting for Enrichment Seals

Generally, sections of road which have had an enrichment seal applied do not require spotting as long as re-painting occurs more than six weeks after the enrichment seal. After this time, the existing line will typically 'bleed through' to a suitably visible extent from which to re-mark.

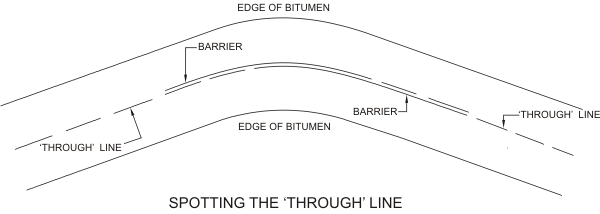

If the existing line does not come through sufficiently after six weeks, the ends of each dash should be spotted on the existing alignment. Where solid barrier lines are encountered the 'through line' (see figure 1) should be spotted.

If line-marking is to take place before existing lines 'bleed through', or there is insufficient definition to re-establish the lines, the alignments should be spotted.

3.6 Barrier Lines Marking

The marking of barrier line locations to create no-overtaking zones shall be undertaken in accordance with latest/current Australian Standard AS 1742.2: Manual of uniform traffic control devices Part 2: Traffic control devices for general use.

( Refer to section 5.3 Longitudinal Lines in the version 1742.2-2009, current as at 10/11/2020).

For Pattern Change Marks, refer to Main Roads Standard Drawing 201331-0026.

For barrier line marking assessment, refer to the Barrier Line Marking Guideline.

3.7 Spotting Through Existing Lines

Where the spotted line adjoins an existing barrier the 'through line' (see figure 1) should be the spotted line. Where new seal encroaches upon each end of the barrier, adopt one line and maintain continuity into and out of the barrier section

(Figure 1)

Care should be taken to provide properly aligned, uniform spotting that enables the line marking operator to establish a line of acceptable standard and appearance.

4. Offsetting Existing Road Markings Prior to Maintenance

On kerbed roads, existing road markings should be marked (offset) in relation to an adjacent fixed structure or object (such as the kerb face) prior to maintenance works. The offset should be marked on the structure or object in an unobtrusive manner using a removable material such as lumber crayon.

On un-kerbed roads, existing road markings should be offset with a mark or peg located outside the work area such that it will not be disturbed.

Sufficient offsets should be provided to ensure spotting results in road markings in the correct position when the road is reinstated.